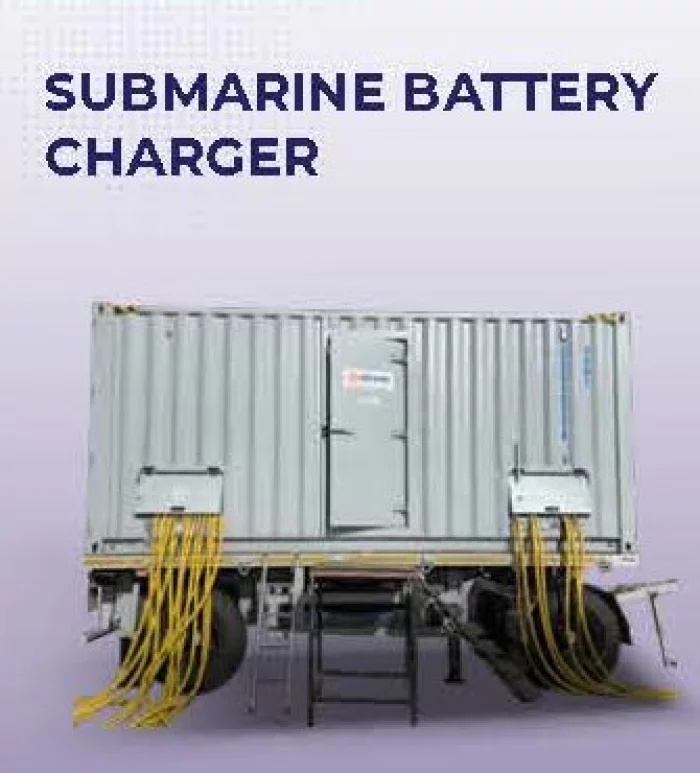

Submarine Battery Changer Mobile and Stationary

A submarine battery charger replenishes propulsion batteries using high-voltage DC power (200-550V) with adjustable currents up to 4000 A DC. It offers normal, rapid, and maintenance modes, employing thyristor control for precise regulation, plus safety features like overvoltage protection and emergency shutdown.

Voltage :

up to 550 V DC

Current :

up to 4000 A DC can be customizable depends upon requirement of the end user

Description

More Products & Services

Products & Services

Submarine Battery Discharger Mobile or Stationary

Neo Power Electronic & Projects Pvt. Ltd

Neo Power Electronics' submarine battery dischargers, available in both mobile and stationary configurations, provide precise and reliable battery maintenance for naval applications. Designed to handle high-capacity submarine batteries, these systems operate at 500 V DC with dual 4000 A DC capacity, ensuring controlled discharge cycles that prevent battery damage while maximizing longevity. Featuring automatic current regulation, they maintain optimal depth of discharge and integrate PLC/PC-based monitoring for real-time data acquisition, allowing users to track voltage, current, temperature, and discharge curves. Mobile units offer flexibility for onboard or dockside operations, while stationary models provide a stable setup ideal for naval bases or submarine Battery Energy Station. By automating battery monitoring and enhancing operational efficiency, these dischargers support naval fleets with advanced technology, reliability, and adaptability, ensuring submarine batteries remain in peak condition for mission readiness.

SS 126 Submarine Battery for 209 Class Submarine

Neo Power Electronic & Projects Pvt. Ltd

Capability to Match Platform requirement of the 209 Class Submarine

Warship / Submarine / Aircraft Carrier AC – DC Generator Testing Load Bank

Neo Power Electronic & Projects Pvt. Ltd

Neo Power specializes in the design and manufacturing of load banks for testing AC generators under various overloading conditions and power factor parameters. Their systems use a computerized data acquisition system to analyze essential performance metrics during AC / DC generator operation.

Their mobile or stationery resistive/inductive load banks range from 100 kW to 4 MW, incorporating resistive and inductive loads, control panel relays, PLC panels, switchgears, breakers, and forced air cooling mechanisms to efficiently dissipate heat. The entire unit is trolley-mounted with a weather-protective canopy, ensuring durability in diverse environments.

Their mobile or stationery resistive/inductive load banks range from 100 kW to 4 MW, incorporating resistive and inductive loads, control panel relays, PLC panels, switchgears, breakers, and forced air cooling mechanisms to efficiently dissipate heat. The entire unit is trolley-mounted with a weather-protective canopy, ensuring durability in diverse environments.

Supplier of Avionics Specifically for Sukhoi Aircraft

Neo Power Electronic & Projects Pvt. Ltd

Approved by Indian military certification agencies, it has been inducted into Indian Air Force aircraft, with over 1,500 units delivered. Additionally, it is deployed in Southeast Asian Air Force aircraft, ensuring advanced avionics reliability for military operations.

In House Commissioning Services for Submarine Battery 209 Class and Scorpene Class Submarine

Neo Power Electronic & Projects Pvt. Ltd

In-house commissioning services for Submarine Battery 209 Class and Scorpene Class Submarine Neo Power play a critical role in ensuring optimal functionality, safety, and operational readiness for submarine propulsion systems. These services encompass a comprehensive set of procedures, including detailed inspections, rigorous testing, integration, and validation of the battery systems. The commissioning process is designed to verify that the batteries meet stringent performance and compliance standards, ensuring their capability to support underwater endurance and manoeuvrability. Expert engineers conduct thorough evaluations to assess electrical efficiency, charge-discharge cycles, thermal management, and overall battery reliability under real-world submarine operating conditions. The integration phase involves seamlessly incorporating the battery systems into the existing electrical and propulsion frameworks, ensuring compatibility and synchronization with submarine control mechanisms. Additionally, validation testing is conducted to certify that the batteries can sustain prolonged deep-sea missions while maintaining peak energy output and resilience. Safety assessments are integral to commissioning, ensuring risk mitigation measures are in place to prevent battery malfunctions that could compromise submarine operations. The in-house approach allows specialized teams to work within controlled environments, optimizing precision and efficiency while reducing potential delays associated with outsourcing. Beyond technical verification, these services contribute to extending battery lifespan, enhancing sustainability, and minimizing maintenance requirements, thereby improving overall submarine operational capability and cost-effectiveness. With cutting-edge diagnostics, adherence to naval regulations, and expert oversight, in-house commissioning services ensure that submarine batteries meet the highest industry standards, providing submarines with the reliable power they require to navigate the depths with confidence and strategic superiority.

Comprehensive Shore Support Facility for Submarine Battery Maintenance and Energy Station

Neo Power Electronic & Projects Pvt. Ltd

Neo Power Electronics & Projects Pvt. Ltd. offers a Comprehensive Shore Support Facility for submarine battery maintenance and energy stations, ensuring efficient and reliable power management for naval applications. Their solutions include mobile battery chargers, dischargers, Frequency converter, chilling plants, high-pressure air compressors, and trickle chargers, all designed to support submarine batteries while docked.

Additionally, Neo Power provides fume extraction systems, pollution control mechanisms, and power factor correction networks to enhance operational efficiency and environmental safety. Their expertise extends to submarine battery commissioning plants, incorporating electrolyte preparation, hydrogen monitoring, and cooling systems to maintain battery performance.

These facilities are tailored to meet the needs of 209 Class and Scorpene Class submarines, ensuring optimal battery health and longevity.

Additionally, Neo Power provides fume extraction systems, pollution control mechanisms, and power factor correction networks to enhance operational efficiency and environmental safety. Their expertise extends to submarine battery commissioning plants, incorporating electrolyte preparation, hydrogen monitoring, and cooling systems to maintain battery performance.

These facilities are tailored to meet the needs of 209 Class and Scorpene Class submarines, ensuring optimal battery health and longevity.

People

Description

Neo Power India's submarine battery chargers are designed to provide reliable and efficient power management for naval applications. These high-power mobile chargers support delivering 380V to 550V DC with a current output of up to 4000 A DC. Utilizing thyristor-based regulation, they ensure precise voltage and current control, optimizing battery performance and longevity. Advanced PC/PLC-based monitoring systems enable real-time data logging and cycle tracking, enhancing operational efficiency. For maintenance, trickle chargers supply 10 to 50 A DC to sustain battery health during idle periods.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link