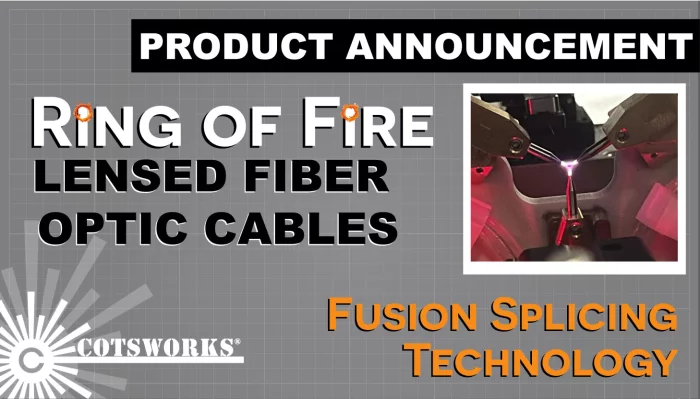

Ring of Fire: New Lensed Fiber Offering From COTSWORKS

COTSWORKS is now offering services to manufacture fiber optic cables with lenses formed at the end of the fiber cable. his technology is fast becoming a requirement for the aerospace industry utilizing optical sensing at Ultraviolet, near infrared, or other application defined wavelengths.

Details

More Products & Services

Products & Services

Rugged Optical Transceivers

COTSWORKS

COTSWORKS offers a variety of transceivers with electrical interfaces enabling pluggable, surface mount, or

thru-hole solder attach. Optical interfaces include industry-standard LC, COTSWORKS’ unique ruggedized

metal LC, ARINC 801, or pigtails. All transceivers operate at industrial temperatures as defined in MIL-STD-883

or MIL-STD-810-type environments. Standard or custom components meet shock, vibration, temperature,

mechanical force, and environmental compliances.

thru-hole solder attach. Optical interfaces include industry-standard LC, COTSWORKS’ unique ruggedized

metal LC, ARINC 801, or pigtails. All transceivers operate at industrial temperatures as defined in MIL-STD-883

or MIL-STD-810-type environments. Standard or custom components meet shock, vibration, temperature,

mechanical force, and environmental compliances.

Complex Cable Assemblies

COTSWORKS

COTSWORKS offers a wide range of robust, reliable, and high-performing fiber optic cable assemblies and

harnesses to support customers working to integrate optical communication into their systems. Focusing on

ruggedized and harsh environment applications, COTSWORKS brings their expertise as an industry leader in

the Fiber Optic Transceiver space into the fiber optic interconnect market. Combining in-house component

designs with qualified connectors termini and cable sourcing, COTSWORKS produces finished flight-ready

assemblies to meet or exceed the requirements of the commercial and military aerospace environments.

COTSWORKS works with customers from the initial design phase through the manufacturing process, and

provides support for these assemblies years after initial installation.

harnesses to support customers working to integrate optical communication into their systems. Focusing on

ruggedized and harsh environment applications, COTSWORKS brings their expertise as an industry leader in

the Fiber Optic Transceiver space into the fiber optic interconnect market. Combining in-house component

designs with qualified connectors termini and cable sourcing, COTSWORKS produces finished flight-ready

assemblies to meet or exceed the requirements of the commercial and military aerospace environments.

COTSWORKS works with customers from the initial design phase through the manufacturing process, and

provides support for these assemblies years after initial installation.

Essential™

COTSWORKS

The Essential™ is low profile, rugged pluggable optical transceiver. Available in duplex, dual TX, dual RX or BiDi configurations on Multimode and Singlemode wavelengths. Operating at 1-28Gbps with compliance to IEEE 1-25Gbps Ethernet, 1-21Gbps Fibre Channel, Infiniband, sFPDP, XAUI, FC-AV/ARINC 818 and other standard protocols. The Essential™ is electrically pluggable to a wave-solderable connector and utilizes screws for operation in high shock and vibration environments. Essential™ boasts a superior optical link budget and an embedded ARINC 801 fiber interface.

SPOT - Secure Parallel Optical Transceivers

COTSWORKS

SPOT™ and SPOT-CE™ are a platform of parallel transceivers with 4Tx and 4Rx channels at 850nm SX/SR standard, SPOT and SPOT-CE offer configurations operating at 1/10/40Gbps data rates. The electrical connector is a high-tolerance industry standard QSFP electrical connector. It mates with a 1-28Gbps surface mount receptacle enabling easy installation and direct upgrade to the 10/28Gbps version of SPOT/SPOT-CE in development.

Description

COTSWORKS is now offering services to manufacture fiber optic cables with lenses formed at the end of the fiber cable. This technique optimizes the coupling efficiency by carefully managing the spot size and placement from an emitter or into a detector. This technology is fast becoming a requirement for the aerospace industry utilizing optical sensing at Ultraviolet, near infrared, or other application defined wavelengths. By integrating cutting-edge technology in our manufacturing processes, COTSWORKS offers very high-quality solutions tailored for harsh environments.

Current equipment utilizes the “Ring of Fire” which is fusion splicing technology developed by 3SAE Technologies. It is designed to perform high-quality splicing of specialty optical fibers including those with large cladding diameters or non-standard coatings which are challenging to process with standard fusion splicers. The “Ring of Fire” technology produces a ring-shaped plasma arc. This results in uniform heating around the fiber tip which minimizes loss and accommodates specialty fiber coatings. It also achieves a higher temperature than standard fusion splice equipment supporting the specialty fiber use and improved end face control.

Cables can be of bare, buffered, coated, jacketed types and made with multimode glass in multiple diameters. Endface images and IL and RL testing are available along with OTDR or OBR traces as well if required. Cables can be processed in or along with media processed within the FORCE clean room for applications ranging from imaging sensors, targeting spots, or space applications.

Contact sales@cotsworks.com for more information.

Current equipment utilizes the “Ring of Fire” which is fusion splicing technology developed by 3SAE Technologies. It is designed to perform high-quality splicing of specialty optical fibers including those with large cladding diameters or non-standard coatings which are challenging to process with standard fusion splicers. The “Ring of Fire” technology produces a ring-shaped plasma arc. This results in uniform heating around the fiber tip which minimizes loss and accommodates specialty fiber coatings. It also achieves a higher temperature than standard fusion splice equipment supporting the specialty fiber use and improved end face control.

Cables can be of bare, buffered, coated, jacketed types and made with multimode glass in multiple diameters. Endface images and IL and RL testing are available along with OTDR or OBR traces as well if required. Cables can be processed in or along with media processed within the FORCE clean room for applications ranging from imaging sensors, targeting spots, or space applications.

Contact sales@cotsworks.com for more information.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link