Precision Dispensing

Automation in Aerospace Manufacturing

Gentle Product Handling

Full support in early project developments

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

ViscoTec Pumpen- u. Dosiertechnik GmbH is a leading system manufacturer for fluid technology: from extraction and product preparation to the dosing of medium to high-viscosity media.

Toeging am Inn, Amperstrasse 13, Germany

Aerospace

Products & Services

People

About

Products & Services

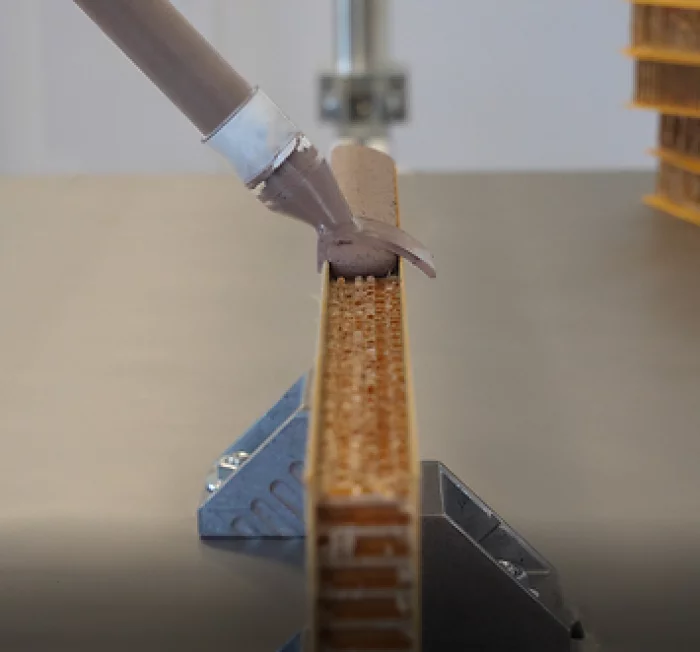

Edge Filling – Dosing of Edge Fillers

ViscoTec Pumpen- u. Dosiertechnik GmbH

In addition to honeycomb potting, sandwich components often also have to be sealed and thus reinforced in the edge areas. For this purpose, similar or even identical filling materials are used as those used for filling the honeycombs themselves. Namely, core and edge filling compounds with very low density, which is achieved by enriching the material with hollow spheres.

With our dosing technology, this process can also be automated. The 1-component or 2-component materials are processed gently – without changing their material properties. The material application can be fully automated or semi-automated. Thanks to pulsation-free dispensing, the best results can be achieved with the minimum of effort. This allows you to reduce production times while optimizing production processes at the same time.

With our dosing technology, this process can also be automated. The 1-component or 2-component materials are processed gently – without changing their material properties. The material application can be fully automated or semi-automated. Thanks to pulsation-free dispensing, the best results can be achieved with the minimum of effort. This allows you to reduce production times while optimizing production processes at the same time.

Seal Caps with vipro-DUOMIX

ViscoTec Pumpen- u. Dosiertechnik GmbH

The static-dynamic mixer vipro-DUOMIX is perfectly suited for compressible, two-component materials – with very different viscosities, extreme mixing ratios and high-pressure sensitivity. The extended version with optimized mixing blocks for low-viscosity, and high-viscosity materials on either side brings a further advantage: It is ideally suited for materials that are difficult to mix – with different or identical viscosities. A modular design with five different dispenser sizes per side allows complete flexibility. And a wide range of mixing ratios from 1:1 to 100:1.

The vipro-DUOMIX can be used for complex two-component applications in diverse industries such as automotive manufacturing, aerospace, or electronics. Irrelevant of whether it is for a dot dispensing, a bead application or for a potting application. Particularly in the production of aircrafts the static-dynamic mixer is used for honeycomb potting or for edge sealing. Special nozzles with adjustable bead width are available for this purpose.

A wide range of two-component materials based on e.g., polyether, epoxy resin, silicone or polyurethane can be dispensed in all areas of application. Due to the parallel alignment of the dispensers, and due to a weight-optimized design, the vipro-DUOMIX is very compact – ideal for assembly in robotic cells or for automated applications.

The vipro-DUOMIX can be used for complex two-component applications in diverse industries such as automotive manufacturing, aerospace, or electronics. Irrelevant of whether it is for a dot dispensing, a bead application or for a potting application. Particularly in the production of aircrafts the static-dynamic mixer is used for honeycomb potting or for edge sealing. Special nozzles with adjustable bead width are available for this purpose.

A wide range of two-component materials based on e.g., polyether, epoxy resin, silicone or polyurethane can be dispensed in all areas of application. Due to the parallel alignment of the dispensers, and due to a weight-optimized design, the vipro-DUOMIX is very compact – ideal for assembly in robotic cells or for automated applications.

Edge Sealing for Structural Components

ViscoTec Pumpen- u. Dosiertechnik GmbH

Wing shells, side shells and fuselage sections are usually made of carbon fibre composites and glued together during the production process. With many components, a groove or an open edge remains after the bonding process, which must be filled or sealed.

A modified two-component epoxy resin is often mixed and then applied manually. This often entails long production times and complex quality controls. Equally high material costs due to the processing of materials from cartridges.

ViscoTec defies short pot life and materials that are difficult to handle: Thanks to a coherent overall system from material removal to material application, this process can be automated. The two components are taken separately from cartridges, hobbocks or drums and fed via hose lines to a two-component dosing system. Only at the very end of the process they are mixed in a static mixing tube and applied to the substrate (e.g. via a nozzle). The process is controlled and monitored by pressure sensors.

A modified two-component epoxy resin is often mixed and then applied manually. This often entails long production times and complex quality controls. Equally high material costs due to the processing of materials from cartridges.

ViscoTec defies short pot life and materials that are difficult to handle: Thanks to a coherent overall system from material removal to material application, this process can be automated. The two components are taken separately from cartridges, hobbocks or drums and fed via hose lines to a two-component dosing system. Only at the very end of the process they are mixed in a static mixing tube and applied to the substrate (e.g. via a nozzle). The process is controlled and monitored by pressure sensors.

Honeycomb Potting

ViscoTec Pumpen- u. Dosiertechnik GmbH

Our products are used for manufacturing interior design components for civil and military aircraft construction. Sandwich structures are used in many areas of an aircraft (storage compartments, interiors, wings) to reduce weight. In order to structurally strengthen the honeycombs or insert them, they often have to be filled during the production process. Typical materials are one- and two-component epoxy resins with a very high proportion of hollow glass spheres. These require extremely gentle handling, as they would otherwise be destroyed, which in turn would result in an increase in density. Common application patterns are beads, circles, full surfaces and egde-filling.

The job is often done manually, which results in long production times and high running costs due to material waste. Lack of reproducibility is just as problematic as the health hazard often posed by these media.

The ViscoTec solution: Material is continuously fed to the dosing system by removal from a large container. With the help of a robot or axis system, suitable structures can be mapped reliably. A coordinated overall system delivers a dispensing result according to specification, in which operator interaction is reduced to a minimum.

The job is often done manually, which results in long production times and high running costs due to material waste. Lack of reproducibility is just as problematic as the health hazard often posed by these media.

The ViscoTec solution: Material is continuously fed to the dosing system by removal from a large container. With the help of a robot or axis system, suitable structures can be mapped reliably. A coordinated overall system delivers a dispensing result according to specification, in which operator interaction is reduced to a minimum.

Automated Insert Potting / Insert Bonding

ViscoTec Pumpen- u. Dosiertechnik GmbH

Inserts are used in the aerospace industry in lightweight sandwich panels and are then bonded. The panels can then be screwed or various components can be fastened.

However, the manual process has several disadvantages: Enormous expenditure of time for the manual filling of several thousand inserts, high material waste due to relaxation of the material, and high material costs through the use of cartridges.

ViscoTec can map the filling process automatically. The dispensing process is absolutely precise. A significant amount of material can thus be saved. In addition, material can be supplied from large containers, which in turn lowers purchase prices. Another important advantage: As a rule, no new specifications have to be made since no changes are made to the actual process.

However, the manual process has several disadvantages: Enormous expenditure of time for the manual filling of several thousand inserts, high material waste due to relaxation of the material, and high material costs through the use of cartridges.

ViscoTec can map the filling process automatically. The dispensing process is absolutely precise. A significant amount of material can thus be saved. In addition, material can be supplied from large containers, which in turn lowers purchase prices. Another important advantage: As a rule, no new specifications have to be made since no changes are made to the actual process.

Sealing Applications

ViscoTec Pumpen- u. Dosiertechnik GmbH

Side shells, wing shells and fuselage structures are made of CFK, GFK, aluminium or organic sheets and get connected during production. Sealants are used to seal the connection surfaces.

These are usually two-component polysulphides, which have to be applied in different geometries. Typical applications are: Fillet sealings, oversealings, interface sealings and seal caps.

Due to their properties, polysulfides require very low pressure and shear handling. The compressibility of the fillers contained in the medium requires a high level of expertise and a coherent overall system from material removal to application. With manual application, long production times and high material ejection have a negative influence on the complete process. Complex quality standards are required due to the risk of human error.

With the in-house developments of the vipro-DUOMIX from ViscoTec, this process can be depicted fully automatically. The individual nozzle design is also adapted to each application. The result is a controlled dosage in compliance with the specifications and at the same time the highest repeat accuracy.

These are usually two-component polysulphides, which have to be applied in different geometries. Typical applications are: Fillet sealings, oversealings, interface sealings and seal caps.

Due to their properties, polysulfides require very low pressure and shear handling. The compressibility of the fillers contained in the medium requires a high level of expertise and a coherent overall system from material removal to application. With manual application, long production times and high material ejection have a negative influence on the complete process. Complex quality standards are required due to the risk of human error.

With the in-house developments of the vipro-DUOMIX from ViscoTec, this process can be depicted fully automatically. The individual nozzle design is also adapted to each application. The result is a controlled dosage in compliance with the specifications and at the same time the highest repeat accuracy.

Mobile Mix-on-Demand System

ViscoTec Pumpen- u. Dosiertechnik GmbH

The semi-automatic ViscoTec mix-on-demand station is already in successful use as a mobile system. For reliable mixing and dosing of two-component materials, in situ.

Two-component materials are commonly processed using premix cartridges, hardener rod cartridges or by mixing two components by hand. The disadvantages are obvious: The risk of human error, enormous material waste and high production costs offer every reason for taking the automated route.

With ViscoTec filling stations, epoxy resins, polysulfides and polyurethanes can be removed from larger containers and filled on-demand with the exact quantity required. The dosing is volumetric on a component or a filling container. A typical application is dosing in so-called inserts (thread inserts). The compact arrangement of the components on a mobile frame guarantees the operator maximum flexibility. The design as a stationary system has already been implemented several times.

Two-component materials are commonly processed using premix cartridges, hardener rod cartridges or by mixing two components by hand. The disadvantages are obvious: The risk of human error, enormous material waste and high production costs offer every reason for taking the automated route.

With ViscoTec filling stations, epoxy resins, polysulfides and polyurethanes can be removed from larger containers and filled on-demand with the exact quantity required. The dosing is volumetric on a component or a filling container. A typical application is dosing in so-called inserts (thread inserts). The compact arrangement of the components on a mobile frame guarantees the operator maximum flexibility. The design as a stationary system has already been implemented several times.

About

ViscoTec – Perfectly dosed!

ViscoTec Pumpen- u. Dosiertechnik GmbH is a leading system manufacturer for fluid technology: from extraction and product preparation to the dosing of medium to high-viscosity media. The product portfolio covers dosing and filling applications in the automotive, e-mobility, electronics manufacturing, food processing, aerospace, medical technology, pharmaceutical and many other industries.

The headquarters of the technological market leader is in Toeging a. Inn (Bavaria, near Munich). In addition to an international distributor network, ViscoTec has subsidiaries in the USA, China, Singapore, India, France, Hong Kong, and Denmark and employs around 370 people worldwide.

Numerous sales partners all over the world complete the international distribution network. Next to technically sophisticated solutions to even the most complicated application, ViscoTec is the single point of contact to deliver all components for a complete system: From emptying to preparing and to dosing. This guarantees successful interaction of all components.

All fluids showing a viscosity of up to 7.000.000 mPas can be conveyed and dosed almost pulsation-free and with extremely low shear.

ViscoTec offers comprehensive consulting for every application and, if required, extensive tests will be carried out in close cooperation with the customer. The dosing pumps and systems are perfectly adapted to their respective application whether it is the food sector, the e-mobility industry, the aerospace field, the medical technology, the pharmaceutical industry, electronics manufacturing or many others.

ViscoTec Pumpen- u. Dosiertechnik GmbH is a leading system manufacturer for fluid technology: from extraction and product preparation to the dosing of medium to high-viscosity media. The product portfolio covers dosing and filling applications in the automotive, e-mobility, electronics manufacturing, food processing, aerospace, medical technology, pharmaceutical and many other industries.

The headquarters of the technological market leader is in Toeging a. Inn (Bavaria, near Munich). In addition to an international distributor network, ViscoTec has subsidiaries in the USA, China, Singapore, India, France, Hong Kong, and Denmark and employs around 370 people worldwide.

Numerous sales partners all over the world complete the international distribution network. Next to technically sophisticated solutions to even the most complicated application, ViscoTec is the single point of contact to deliver all components for a complete system: From emptying to preparing and to dosing. This guarantees successful interaction of all components.

All fluids showing a viscosity of up to 7.000.000 mPas can be conveyed and dosed almost pulsation-free and with extremely low shear.

ViscoTec offers comprehensive consulting for every application and, if required, extensive tests will be carried out in close cooperation with the customer. The dosing pumps and systems are perfectly adapted to their respective application whether it is the food sector, the e-mobility industry, the aerospace field, the medical technology, the pharmaceutical industry, electronics manufacturing or many others.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link