Quality Verification and Assembly Gages and Fixtures.

CAD Design and Manufacturing of Fixtures and Gages.

AS9100:2016 and ISO 900:2015 Certification

ISO17025 CMM Lab Accreditation

CLARK FIXTURE TECHNOLOGY

With over 40 years of experience working across multiple industries, Clark Fixtures has become a leader in the quality verification industry. Our focus on quality and customer service has helped us grow to serve clients around the world.

Bowling Green, Ohio (OH), United States

Aerospace, Defense & Security, Healthcare

Products & Services

People

About

Products & Services

CAD/CAM Design Services

Clark Fixture Technology

Clark Fixtures almost from its inception, utilized CAD/CAM as a way to design appropriate tooling around a customer’s product. With guidance from the PE, the appropriate material, design and features are brought together to fulfill the needs of any given project. As each design is completed, it is reviewed and signed off and then put in a format that can be emailed or uploaded to a secure site. Once these designs are approved by the customer, they are integrated back into our production process.

Orbital weld fixture

Clark Fixture Technology

Our custom designed orbital weld fixtures allow an operator to scribe the end of tube locations, assemble the individual tubes together within the fixture and then orbitally weld the assembly and end features together in an efficient and accurate manner. These fixtures have proven to be extremely successful for companies moving from R&D to a production mode, where rate and repeatability are essential.

Manufacturing and machining services

Clark Fixture Technology

With the utilization of CAD/CAM an NC file is sent to the shop server, a full scale plot of the material is sent to the material prep department and drawings for any metal details that need to be machined are sent to the machining department.

The vast majority of our fixtures are machined on CNC machines as one complete part on its base, thereby removing the added tolerance stack-up that is necessary when adding separate blocks or saddles. Quality verifications are taken at every step.

The vast majority of our fixtures are machined on CNC machines as one complete part on its base, thereby removing the added tolerance stack-up that is necessary when adding separate blocks or saddles. Quality verifications are taken at every step.

Engineering services

Clark Fixture Technology

Clark Fixtures brings to the table over 40 years of experience. Our project engineers work with various customers in numerous industries. Their understanding of tolerancing and GD&T come from this experience. As new customers are on-boarded, they are assigned a PE that best fits their industry and products. This technical contact becomes your primary interface with quotes and orders.

Full contour fixture for in process and final audit check

Clark Fixture Technology

The full contour fixture was developed originally by Clark Fixtures. The concept behind it was to replicate the boundaries called out on the print, so that the operator can quickly determine whether the part is good or bad. Various end features are available to check end details.

Quality Inspection Verification Gages and Assembly Fixtures

Clark Fixture Technology

Clark Fixtures custom designs each gage or fixture to customers CAD and specific requirements. Using both composite and all aluminum construction, our gages provide customers the ability to verify and assemble parts at the point of manufacturing. Various cavity designs and contoured milled surfacing allow for parts to be checked and verified very efficiently. All fixtures and gages are checked and certified in our ISO 17025 CMM lab and provided to the customer at time of shipment.

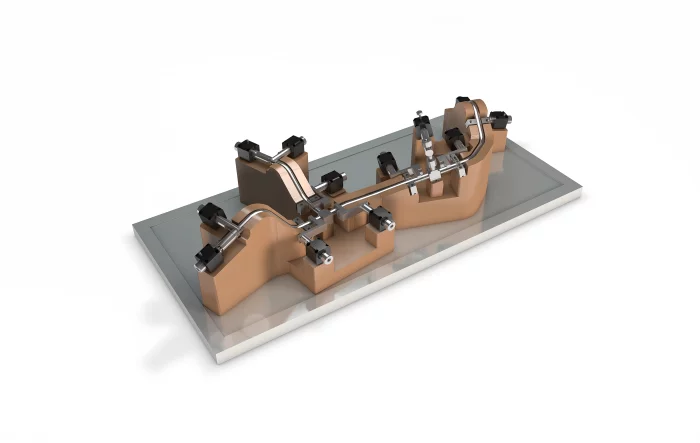

All metal assembly and inspection fixture

Clark Fixture Technology

Although we are known for our composite fixtures, we can also provide a full assortment of metal fixtures for large tubing or welding. Time and time again, our lead-times for metal stanchion fixtures are much better than our competitors and all fixtures are inspected by our 17025 CMM lab. We offer the following fixture types:

Thermal acoustical composite check fixture

Clark Fixture Technology

Check fixtures for engineered thermal acoustical products are designed in our CAD/CAM environment and CNC machined. Utilizing durable composite materials and only placing hardened steel inserts at datum locations or wear points, saves on weight, manufacture time and cost. There is no need to schedule a fork lift to move this fixture to the active work cell.

Large diameter composite fixture

Clark Fixture Technology

Large diameter composite fixtures are ideal for prototype and subassembly parts. Rather than manufacture these fixtures completely out of tool steel we can utilize a durable composite material and place the hardened steel only at the contact points, thereby saving on weight, manufacturing time and cost.

CMM and Inspection services

Clark Fixture Technology

Clark Fixture’s CMM lab is certified to ISO-IEC17025:2017.

Each fixture is rigorously inspected to ensure that the product you are receiving is machined to the specifications that were inputted into its design and matches the print coordinates.

Upon completion a final audit inspection is preformed to confirm that the fixture is complete and functional.

Each fixture is rigorously inspected to ensure that the product you are receiving is machined to the specifications that were inputted into its design and matches the print coordinates.

Upon completion a final audit inspection is preformed to confirm that the fixture is complete and functional.

People

About

With over 40 years of experience working across multiple industries, Clark Fixtures has become a leader in the quality verification industry. Our focus on quality and customer service has helped us grow to serve clients around the world.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link