_300.webp)

1. Industrial Optical Solutions :

Semiconductors, displays, and other industrial applications

2. Defense Industry Optical Solutions :

Seeker domes, laser air defense weapons, and other defense systems

3. Space Optics :

Large mirrors for space applications and space optical systems

4. Materials :

ZnS (Zinc Sulfide)

GREEN OPTICS CO., LTD.

From Design and Fabrication to the Evaluation of Optical components & systems, Green Optics Provides Optical Solution that meet customer needs.

Chungcheongbuk-do, Chungcheongbuk-do, South Korea

Aerospace

Products & Services

People

Other

About

Products & Services

Vis/SWIR Zoom Optics

Green Optics Co., Ltd.

1. Feature

- A common optical system supporting two wavelength bands (visible/SWIR) with a CAM structure, capable of up to 10× magnification.

- A common optical system supporting two wavelength bands (visible/SWIR) with a CAM structure, capable of up to 10× magnification.

ZnS Matetial

Green Optics Co., Ltd.

Green Optics possess proprietary CVD-based Zinc Sulfide (ZnS) production technology for defense and industrial multi-wavelength optical materials. We have core technological capabilities to manufacture high-quality ZnS products tailored to meet diverse customer requirements.

ZnS Material Optical Performance and Processing

ZnS materials produced through CVD processes provide high transmittance exceeding 70% in the SWIR wavelength range (8-12 μm). When these materials undergo additional Hot Isostatic Pressing (HIP) treatment, the crystal structure undergoes recrystallization, improving transmission characteristics to achieve over 70% transmittance in the visible (VIS) wavelength range of 0.45-0.8 μm. This process extends the application range of optical materials previously limited to SWIR and LWIR bands, delivering superior optical performance across multi-wavelength regions from VIS to LWIR.

Material Specifications:

- STD-ZnS (Standard ZnS Material): Manufactured via CVD process, exhibits transmittance exceeding 70% in LWIR wavelengths (8-12 μm) with high physical hardness (Knoop hardness: 210 kgf/mm²).

- MS-ZnS (Multispectral ZnS): Converted from STD-ZnS through HIP processing, extends wavelength range into the visible spectrum. While crystal structure recrystallization during this process reduces hardness somewhat (approximately 150 kgf/mm²), it still meets MIL specifications.

This dual-processing approach enables comprehensive wavelength coverage while maintaining military-grade durability standards.

ZnS Material Optical Performance and Processing

ZnS materials produced through CVD processes provide high transmittance exceeding 70% in the SWIR wavelength range (8-12 μm). When these materials undergo additional Hot Isostatic Pressing (HIP) treatment, the crystal structure undergoes recrystallization, improving transmission characteristics to achieve over 70% transmittance in the visible (VIS) wavelength range of 0.45-0.8 μm. This process extends the application range of optical materials previously limited to SWIR and LWIR bands, delivering superior optical performance across multi-wavelength regions from VIS to LWIR.

Material Specifications:

- STD-ZnS (Standard ZnS Material): Manufactured via CVD process, exhibits transmittance exceeding 70% in LWIR wavelengths (8-12 μm) with high physical hardness (Knoop hardness: 210 kgf/mm²).

- MS-ZnS (Multispectral ZnS): Converted from STD-ZnS through HIP processing, extends wavelength range into the visible spectrum. While crystal structure recrystallization during this process reduces hardness somewhat (approximately 150 kgf/mm²), it still meets MIL specifications.

This dual-processing approach enables comprehensive wavelength coverage while maintaining military-grade durability standards.

Lightweighted off-axis mirror

Green Optics Co., Ltd.

1) Fabrication

- possible Dismension : ~ D 1200 mm

- Surface Errors

PV < 79 nm

RMS < 12 nm

Roughness < 2 nm(Typical < 1nm)

2) Lightweight

- lightweight Ratio : up to 82.5 %

- Rib Thickness : ~ 2 mm

- Face Sheet : ~ 7 mm

- Lightweight Design & Fabrication

- possible Dismension : ~ D 1200 mm

- Surface Errors

PV < 79 nm

RMS < 12 nm

Roughness < 2 nm(Typical < 1nm)

2) Lightweight

- lightweight Ratio : up to 82.5 %

- Rib Thickness : ~ 2 mm

- Face Sheet : ~ 7 mm

- Lightweight Design & Fabrication

High-power laser mirror fabrication technology

Green Optics Co., Ltd.

High-power laser weapons targeting objects at 0.5 ~ 4.0km distances require optical components with sub-nm wavefront error precision. Our Company has successfully developed aspherical polishing and high-power laser coating technologies for Ø300 ~ 550mm optical components through defense project experiences.

measurement technology

1) Laser Induced Damage Threshold(LIDT)

- The evaluation to confirm the durability of optical components is called LIDT (Laser-Induced Damage Threshold), which is defined as "the maximum amount of laser radiation incident on an optical component when the expected probability of damage is zero" (ISO 21254). In other words, it represents the maximum intensity or power of laser that an optical component can withstand, making it a critical requirement in laser weapon systems.

- Our company has established LIDT measurement technology and in-house facilities developed in accordance with ISO 21254 standards. When compared with LIDT test results from domestic and international companies during laser weapon system development, we have demonstrated measurement technology and accuracy that meets or exceeds industry standards. While overseas companies require more than one month for verification processes, our company can immediately provide reliable data through our LIDT system.

2) Cavity Ring Down Spectroscopy(CRDS)

- When the reflectivity is 99.997%, this may not present significant issues in low-power laser applications. However, in high-power laser components, even the 0.05% of light that passes through the optical mirror can cause problems in vulnerable parts of the system, including rear optical instruments, bonded lenses, and control cables. Therefore, measurement and evaluation methods for high-reflectivity optical mirrors are extremely important.

- Currently, the transmittance and reflectance of optical components are generally measured using spectrophotometers, but measuring reflectance levels of 99.5% or higher is not possible with this method. CRDS (Cavity Ring-Down Spectroscopy) technology is required to achieve measurement resolution beyond that of spectrophotometers, and our company has established this system to measure the reflectance of various optical components. This is a critically important technology for responding to high-power laser weapon system development requirements.

measurement technology

1) Laser Induced Damage Threshold(LIDT)

- The evaluation to confirm the durability of optical components is called LIDT (Laser-Induced Damage Threshold), which is defined as "the maximum amount of laser radiation incident on an optical component when the expected probability of damage is zero" (ISO 21254). In other words, it represents the maximum intensity or power of laser that an optical component can withstand, making it a critical requirement in laser weapon systems.

- Our company has established LIDT measurement technology and in-house facilities developed in accordance with ISO 21254 standards. When compared with LIDT test results from domestic and international companies during laser weapon system development, we have demonstrated measurement technology and accuracy that meets or exceeds industry standards. While overseas companies require more than one month for verification processes, our company can immediately provide reliable data through our LIDT system.

2) Cavity Ring Down Spectroscopy(CRDS)

- When the reflectivity is 99.997%, this may not present significant issues in low-power laser applications. However, in high-power laser components, even the 0.05% of light that passes through the optical mirror can cause problems in vulnerable parts of the system, including rear optical instruments, bonded lenses, and control cables. Therefore, measurement and evaluation methods for high-reflectivity optical mirrors are extremely important.

- Currently, the transmittance and reflectance of optical components are generally measured using spectrophotometers, but measuring reflectance levels of 99.5% or higher is not possible with this method. CRDS (Cavity Ring-Down Spectroscopy) technology is required to achieve measurement resolution beyond that of spectrophotometers, and our company has established this system to measure the reflectance of various optical components. This is a critically important technology for responding to high-power laser weapon system development requirements.

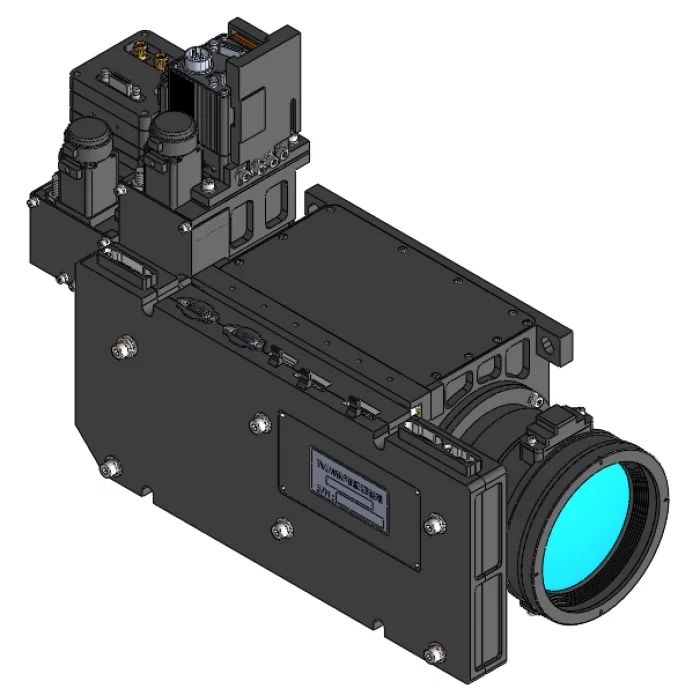

Vis/SWIR 2FoV Optics

Green Optics Co., Ltd.

1. Feature

- An equipment combining visible and short-wave infrared (SWIR) cameras, capable of daytime reconnaissance, surveillance, and target acquisition, applicable to various systems.

- It can be mounted on and integrated with various types of weapon systems.

- With SWIR mode, targets can be monitored, tracked, and acquired even in conditions with haze, fog, or dust.

- An equipment combining visible and short-wave infrared (SWIR) cameras, capable of daytime reconnaissance, surveillance, and target acquisition, applicable to various systems.

- It can be mounted on and integrated with various types of weapon systems.

- With SWIR mode, targets can be monitored, tracked, and acquired even in conditions with haze, fog, or dust.

MS60

Green Optics Co., Ltd.

It is a product produced in Korea and has high performance when used in EO/IR Gimbal for small drones.

It can view both VIS and IR images simultaneously and is coupled to a small drone with a small weight to perform operations. Products with manufactured and domestic IR sensors in Korea.

we deliver superior technologies that shape the future of defense. Whether supporting ISR missions or enhancing precision in loitering munition operations, MS60 products are designed to ensure operational excellence in the most challenging environments.

It can view both VIS and IR images simultaneously and is coupled to a small drone with a small weight to perform operations. Products with manufactured and domestic IR sensors in Korea.

we deliver superior technologies that shape the future of defense. Whether supporting ISR missions or enhancing precision in loitering munition operations, MS60 products are designed to ensure operational excellence in the most challenging environments.

About

Green Optics is an optical manufacturing specialist focused on producing high-value-added optical components and developing optical system equipment. We are a systems company based on optics that competes with global optical industry leaders such as Nikon, Canon, and Carl Zeiss. Optics technology can be compared to creating eyes for the human body. Unlike conventional camera lenses, we design, process, coat, assemble, and evaluate ultra-precision optical components, providing comprehensive optical solutions from start to finish.

Core Capabilities

Based on our comprehensive optical solutions, we produce optical products for various fields ranging from cutting-edge industries such as semiconductors and displays to defense industries and satellites. We possess comprehensive capabilities that encompass the entire optical field, including:

- Opto-mechanics design for optical application products

- Fabrication(Shaping, Grinding, Polishing, Coating)

- Assembly

- Evaluation

Core Capabilities

Based on our comprehensive optical solutions, we produce optical products for various fields ranging from cutting-edge industries such as semiconductors and displays to defense industries and satellites. We possess comprehensive capabilities that encompass the entire optical field, including:

- Opto-mechanics design for optical application products

- Fabrication(Shaping, Grinding, Polishing, Coating)

- Assembly

- Evaluation

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link